What are the specific requirements for the precision environment needed for a lithography machine?

Release time:

2025-08-07

Currently, Jice (Nanjing)'s high-precision environmental control equipment has achieved a maximum temperature control accuracy of ±0.002℃ and a cleanliness level of class 10 or higher.

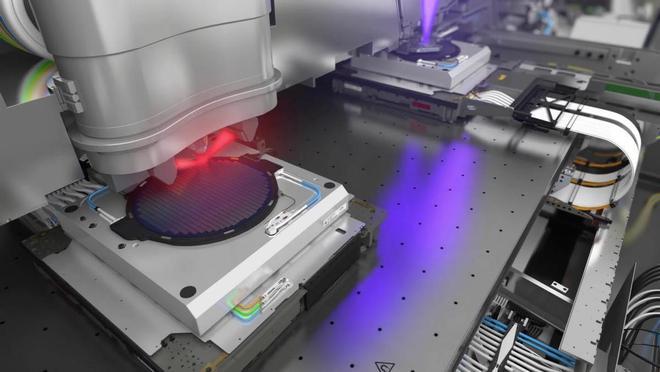

Lithography machines are core equipment in semiconductor manufacturing. Their function is to precisely transfer integrated circuit patterns from a mask onto a wafer coated with photoresist via optical projection, achieving the graphical transfer process of circuit patterns. In the chip manufacturing process, lithography is the most complex and costly process step, accounting for one-third of the total wafer manufacturing cost and 40%-60% of the time, directly determining the chip's process precision and production yield.

Its core principle is to use a high-energy laser as a light source. After the light beam passes through the mask, it is reduced by a 1/16 ratio through a condenser lens system, then precisely focused on the wafer surface, causing the photoresist to undergo a photosensitive reaction, thus completing the high-precision replication of the circuit pattern. It's like engraving a city map on a hair, the complexity and technical challenges are imaginable, and it also has extremely high requirements for the operating environment.

These precision requirements are mainly reflected in the following aspects:

1. Temperature Stability:

The optical components (such as lenses, mirrors) and precision mechanical structures inside the lithography machine are mostly made of materials that are extremely sensitive to temperature. Minor temperature changes will cause thermal expansion and contraction of the materials, causing the optical system's focal length to shift, the alignment system to misalign, and the mechanical platform to drift, ultimately leading to pattern distortion, increased overlay errors, and a sharp drop in yield. The entire lithography area is usually under constant temperature control.

2. Humidity Stability:

Excessive humidity may cause condensation on the surface of optical lenses, corrosion of metal parts, and changes in the properties of the photoresist; excessively low humidity easily generates static electricity, attracting dust to contaminate the wafer and equipment. Precise humidity control is crucial for ensuring process stability and material performance.

3. Ultra-Low Vibration:

Lithography machines require extremely high stability during exposure. Any vibration from the ground (traffic, construction, people walking), the equipment itself (air conditioning, pumps), or the building (wind load) will directly cause the optical system to shake, making the pattern projected onto the silicon wafer blurry or offset. Therefore, lithography machines are usually installed on independent foundations deep underground or on high-performance active/passive vibration isolation platforms, and even use technologies such as magnetic levitation for active vibration damping.

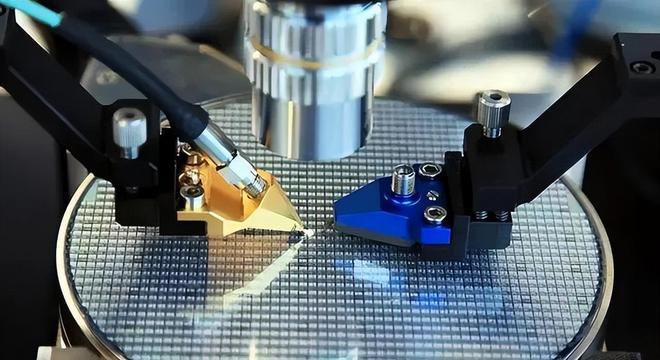

4. Ultra-Clean Environment:

A dust particle larger than the feature size of the exposure pattern falling on the mask or wafer can block light, causing pattern defects or open circuits. At the nanoscale, even extremely small particles are deadly. The entire lithography area is located in a highest-level cleanroom, with the air passing through multiple stages of high-efficiency filtration, and strict purification procedures for personnel and materials entering and exiting.

5. Airflow Stability:

Stable laminar flow can effectively and smoothly remove particles and heat generated during the process, preventing particles from settling on the wafer surface and maintaining the temperature uniformity within the area. Turbulent airflow will stir up particles and may cause temperature fluctuations.

6. Anti-Static and Electromagnetic Shielding:

Static electricity will attract dust to contaminate the wafer and equipment, and even break down sensitive microelectronic structures. The precise sensors, control systems, and measurement systems (such as laser interferometers) inside the lithography machine are very susceptible to interference from external electromagnetic fields, leading to measurement inaccuracies or control errors.

Extreme Measurement (Nanjing) Focuses on precision environmental control solutions, currently serving many leading global semiconductor, communication equipment, and display panel companies and national key laboratories, applied in numerous scientific research and production scenarios.

Currently, High-precision environmental control equipment has achieved a maximum temperature control accuracy of ±0.002℃ and a cleanliness level of class 10 or higher. Possessing the ability to customize non-standard solutions for all scenarios, it can meet the different environmental parameters and usage needs of users, such as temperature and humidity stability, cleanliness, anti-vibration, anti-magnetic, sound insulation, etc. , continuously leading the innovation of ultra-high precision environmental control technology.

Here is the title one h1 placeholder text

More news