Ultra-Precision Cooling Water Chiller

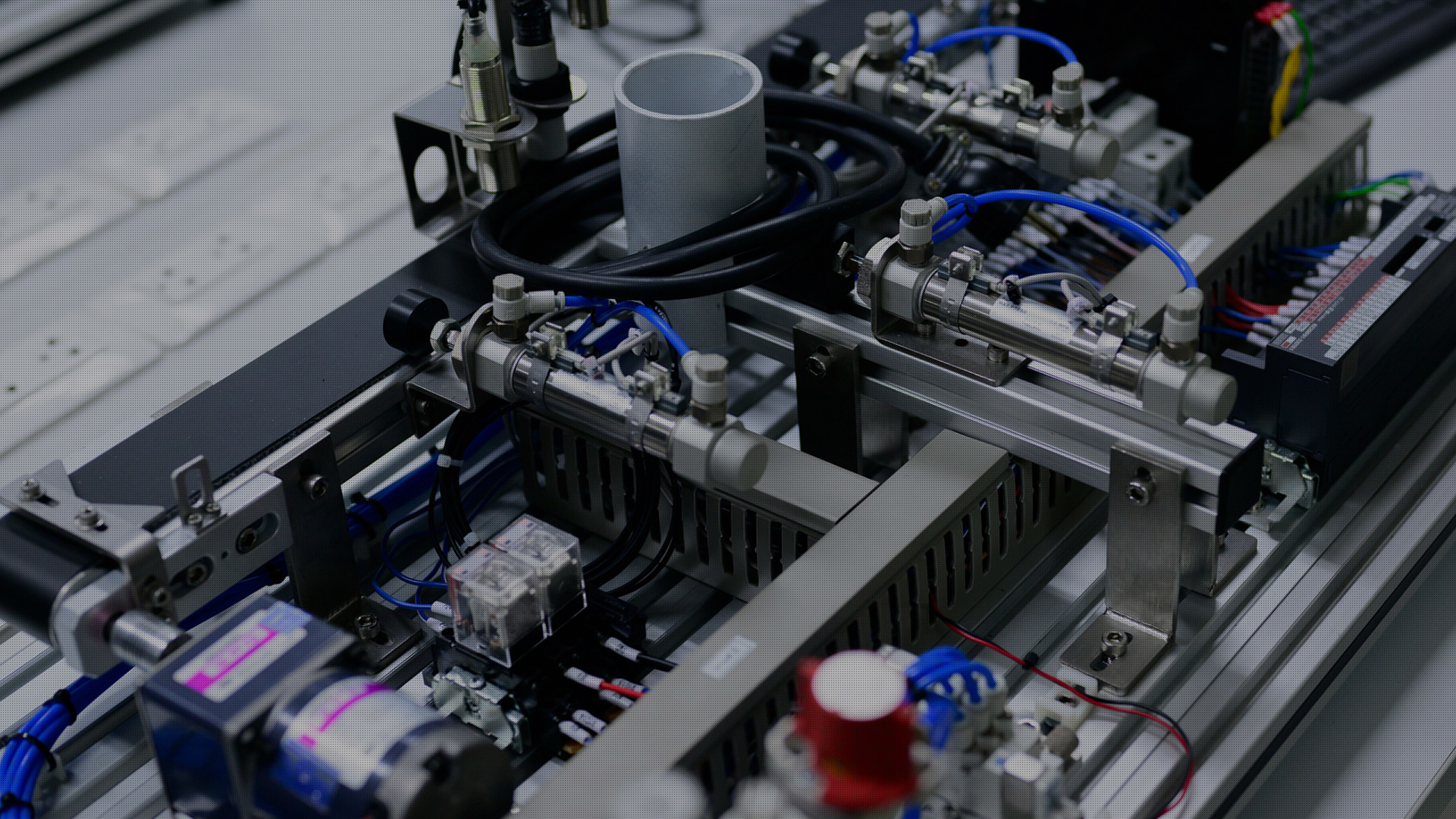

Using self-developed temperature control technology, the maximum accuracy of the chilled water outlet temperature can reach ±0.002℃.

A large color touch screen is used to display all information, showing the real-time changes in the outlet water temperature in the form of a curve.

Large capacity historical data storage, equipped with USB and Ethernet interfaces, convenient for exporting historical data. Support MODBUSTCP/IP protocol, real-time online detection data.

The equipment is equipped with complete safety protection functions such as overload protection, liquid level monitoring, and leakage detection, making the equipment run more safely and stably.

Typical Application

Laboratories and Research Institutions

Ensure experimental result accuracy and reliability in facilities such as microbiology labs, animal housing, and supercomputing centers. Maintain temperature stability for lithography machines, particle accelerators, and other critical equipment.

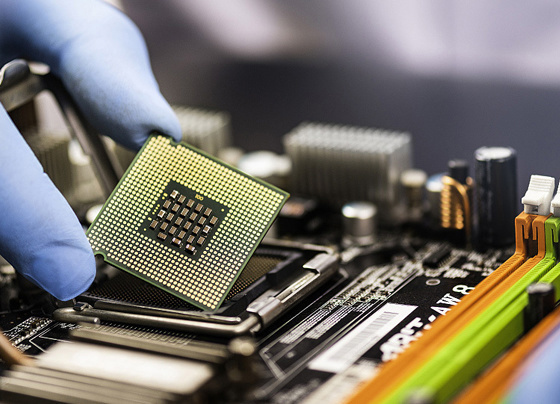

Semiconductor Manufacturing

Support chip processing, component assembly, and production line cooling to mitigate thermal stress on precision components and improve yield rates.

Electronic Component Production

Stabilize internal structures of electronic elements for ultrasonic cleaning, vacuum coating processes, while controlling solvent evaporation and ensuring coating quality.

Medical Equipment Manufacturing

Address cooling requirements for laser medical devices and cryogenic biological sample storage. Low-noise designs comply with hospital environmental standards.

Plastics and Injection Molding

Precisely regulate mold temperature to shorten injection molding cycles and enhance product consistency. Compatible with cooling systems for injection/blow molding machines.

Food Processing and Preservation

Enable rapid cooling and fermentation temperature control to maintain packaging integrity and food safety standards, applicable in meat processing and dairy production.

Mechanical Manufacturing and Precision Assembly

Deliver cryogenic treatment (e.g., bearing shrink-fit assembly) and ultra-low temperature testing (aerospace components) to enhance material hardness and assembly accuracy.

Data Centers and Communication Infrastructure

Provide high-efficiency cooling for server rooms and supercomputing facilities, leverage natural cooling sources to reduce energy consumption while ensuring operational stability.

immediate consultation

You can leave us your needs or suggestions online, and we will reply to you as soon as we receive them.