Jice (Nanjing) Semiconductor Temperature Control - Semiconductor Process Temperature Control

Release time:

2025-09-10

Jice (Nanjing) Semiconductor Temperature Control achieves high-precision semiconductor temperature control in the semiconductor process by strictly controlling external environment and internal conditions and adopting advanced control schemes, providing solid support for the precision and high quality of semiconductor manufacturing.

In the semiconductor process, temperature control is a core aspect to ensure production accuracy and efficiency.

Jice (Nanjing) Technology Co., Ltd.

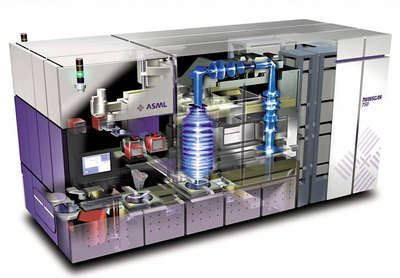

Provides practical semiconductor temperature control solutions. Especially during the operation of lithography machines, a reasonable temperature range, accurate temperature measurement, and control directly affect three important indicators: the resolution of the lithography machine, overlay accuracy, and yield. For a 200mm silicon wafer, a temperature change of only 0.1°C can cause a length variation of about 52.4nm; the core component of the lithography machine—the projection lens—requires even stricter temperature control, with temperature stability needing to reach 0.01°C, fully demonstrating the critical role of semiconductor temperature control in precision manufacturing.

Semiconductor temperature control needs to meet a series of internal and external environmental conditions.

Semiconductor temperature control must meet a series of strict external environmental conditions. Regarding temperature and humidity, the dry-bulb temperature of the surrounding environment must be controlled at 22±2°C, with a temperature change rate within 2°C/h; relative humidity should be 50±5% RH, with humidity change rate maintained within 5%/h. The cleanliness of the surrounding environment must meet ISO class 6 standards, environmental noise controlled below 65dB. Altitude should be between -20 to 2000m, nominal air pressure between 78 to 101.4kPa, with maximum pressure fluctuations not exceeding ±2.5kPa, and pressure gradient ≤2.0kPa/hr and ≤10Pa/10sec. Strict control of these external environmental conditions forms the foundation for Jice (Nanjing) Technology Co., Ltd. to achieve precise semiconductor temperature control.

In addition to the external environment, the internal requirements for semiconductor temperature control are equally stringent. Internal cleanliness in the equipment working area must reach ISO class 4 standards. The internal temperature is set at 22.0°C, with temperature stability in key areas (static) controlled within ±5mK, other areas (static) within ±25mK; temperature spatial uniformity must be less than 16mK/m. Internal humidity stability must be maintained within ±0.8%, internal pressure stability within ±3Pa, internal pressure gradient less than 16Pa/m, and when the equipment is off, the internal noise of the environmental control must be ≤60dB. These internal requirements are established to ensure that semiconductor processes occur in the most suitable microenvironment, further highlighting the precision of this semiconductor temperature control.

To meet the above temperature, humidity, and cleanliness requirements, Jice (Nanjing) Technology Co., Ltd. has adopted ingenious ideas and solutions in the design of semiconductor temperature control. For humidity control, relative humidity is ensured by the external environment, maintaining stable absolute moisture content in the air through large-scale environmental control, thus achieving humidity stability inside the environmental chamber by precise temperature control. For temperature and cleanliness control, a design concept of large air volume with small temperature difference is used, continuously and rapidly circulating air for filtration while removing residual heat in the laboratory and heat generated by maintenance structures, keeping temperature fluctuations at extremely low levels. In key areas, stability can even reach ±0.005°C, effectively ensuring the precision of semiconductor temperature control.

In the temperature control scheme, semiconductor temperature control adopts a multi-stage temperature regulation strategy. Air in the laboratory is first cooled by a surface cooling coil, then gradually heated by multi-stage electric heating. Through this stepwise regulation, temperature accuracy is upgraded from ±0.1°C to ±0.02°C, and finally to ±0.005°C. This multi-stage temperature control method can precisely adjust the temperature, ensuring that the temperature during the semiconductor process remains at the optimal state, providing reliable temperature assurance for the high-quality production of semiconductor products.

Jice (Nanjing) semiconductor temperature control achieves high-precision temperature regulation in the semiconductor process through strict control of external environment and internal conditions, as well as the adoption of advanced control schemes, providing solid support for the precision and high-quality manufacturing of semiconductors.

Here is the title one h1 placeholder text

More news