Precise Temperature Control: Bridging the Gap from Nanometer-Level Error to Micrometer-Level Reliability

Release time:

2025-04-11

Currently, we possess comprehensive capabilities for non-standard customization across various scenarios, catering to users' diverse environmental parameters and usage requirements. This includes personalized needs such as temperature and humidity stability, cleanliness, anti-vibration, anti-magnetic, and sound insulation.

As technology continues to advance into the microscopic realm, the precision industry's demands for temperature control are almost苛刻 (exacting/stringent). Nanjing Expansion Technology's subsidiary, Jice (Nanjing) Technology Co., Ltd., independently researches and produces equipment with

ultra-high precision temperature control capabilities

,becoming a key force in driving industrial upgrades.

Its temperature control accuracy of up to ±0.002℃ and control output accuracy of 0.1% precisely guarantee experimental accuracy and product yield. The internal temperature specification of 22.0°C is flexible, and with temperature uniformity of less than 16mK/m, a stable temperature platform is built for precision processes. Simultaneously, the system can achieve cleanliness control above class 100, with internal cleanliness in the equipment's work area optimally reaching ISO class 1. This high standard meets the pursuit of a pure environment in high-precision fields such as semiconductors and biopharmaceutical research.

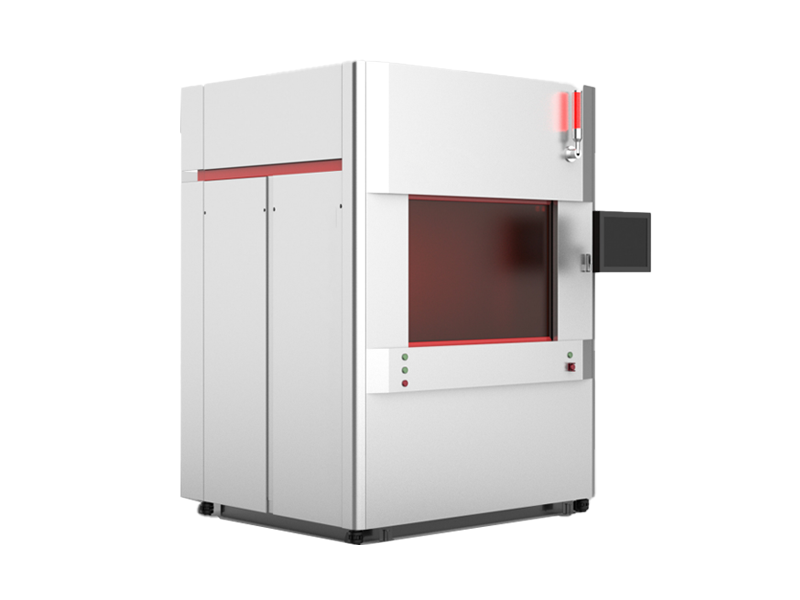

In terms of appearance, the detachable aluminum alloy frame facilitates easy assembly of large equipment, breaking down space limitations. The high-quality sheet metal casing is not only aesthetically pleasing but can also be customized in color according to the customer's design, showcasing Brand individuality.

During equipment operation, the EC fan and high-efficiency sound insulation material work together to keep the operating noise below 45dB, creating a quiet working environment and avoiding noise interference with precision operations. The data real-time recording and query function is powerful; temperature and humidity data automatically generate curves for easy viewing and can be exported as tables at any time. Operation and fault records are clearly traceable, providing strong support for production optimization and quality traceability. The automatic safety protection system further strengthens the safety line for industrial upgrades, with automatic fault protection, real-time audio-visual alarms, and remote assistance for fault handling, ensuring smooth 24/7 production and leading the precision industry to new heights.

Currently, we possess the ability to customize for all scenarios, meeting users' different environmental parameters and usage needs, such as temperature and humidity stability, cleanliness, anti-vibration, anti-magnetic, and sound insulation. We have already served many leading global semiconductor, communication equipment, and display panel companies and national key laboratories, and our applications span numerous scientific research and production scenarios.

Here is the title one h1 placeholder text

More news