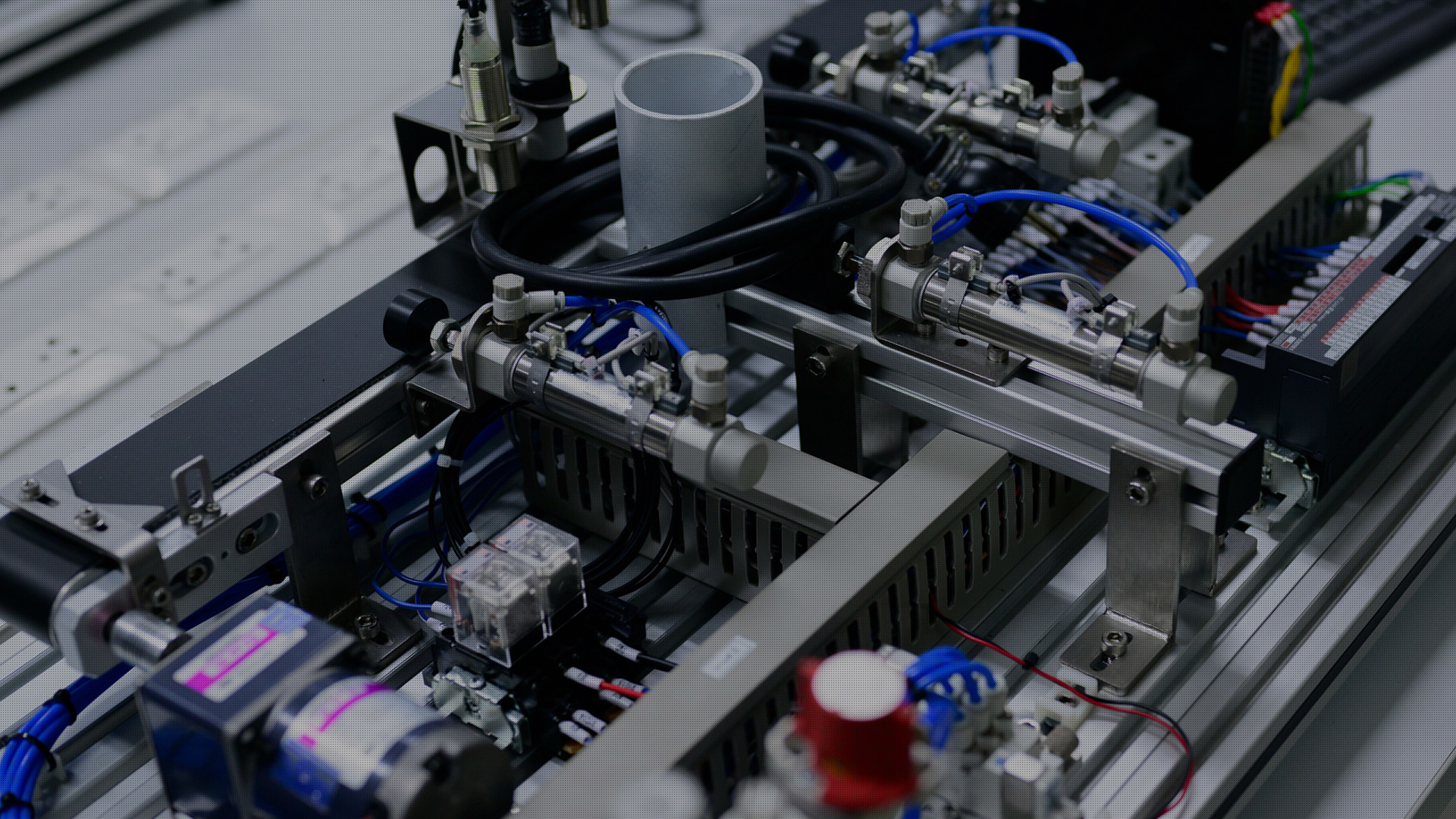

Ultra-Precision Gas Temperature Control Machine

Typical Application

Laboratories and Cleanrooms

Maintain constant humidity environments to ensure precision instrument stability and experimental data accuracy, applicable in biosafety labs, semiconductor cleanrooms, and metrology centers.

Healthcare Sector

Enable sterile humidification for operating theaters and ICU wards, with humidity control in pharmaceutical production facilities and vaccine storage to prevent moisture absorption or electrostatic interference.

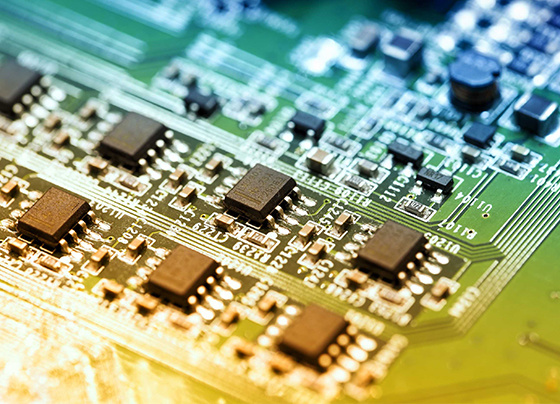

Electronic Component Manufacturing

Implement humidity regulation in cleanrooms for chip packaging and SMT assembly processes, eliminating static electricity to reduce dust adhesion risks and component breakdown.

Modern Agriculture and Plant Factories

Precisely control humidity in greenhouses, tissue culture rooms, and edible mushroom cultivation chambers to enhance crop growth efficiency and fungal cultivation while reducing disease incidence.

Data Centers and Server Rooms

Prevent static buildup damage and avoid circuit board brittleness caused by low humidity, maintaining year-round humidity stability for critical infrastructure.

Printing and Packaging Industry

Regulate workshop humidity to prevent paper deformation and uneven ink drying, improving color registration accuracy and product yield.

Cultural Heritage Preservation

Provide humidity-controlled environments for museums, archives, and ancient document repositories to prevent cracking, mold growth, or metal oxidation.

Automotive Manufacturing

Maintain optimal humidity in painting workshops and component assembly areas to eliminate static electricity while preventing rubber component deformation.

immediate consultation

You can leave us your needs or suggestions online, and we will reply to you as soon as we receive them.