How to create a precision environment with fluctuation of ±0.005℃ and cleanliness of ISO Class 3?

Release time:

2025-04-28

By clarifying goals, building systems, implementing intelligent monitoring, and ensuring thorough maintenance, we can effectively achieve this goal, providing a stable and reliable environment for high-end industries and scientific research activities, and driving the industry towards even higher precision and quality.

In semiconductor manufacturing and precision optical inspection, even slight deviations in environmental parameters can significantly reduce product performance. Achieving temperature control with ±0.005℃ fluctuation and ISO Class 3 cleanliness requires overcoming the technical bottlenecks of traditional environmental control.

A Nanjing-based company under Nanjing Expansion Technology,

Jice (Nanjing)

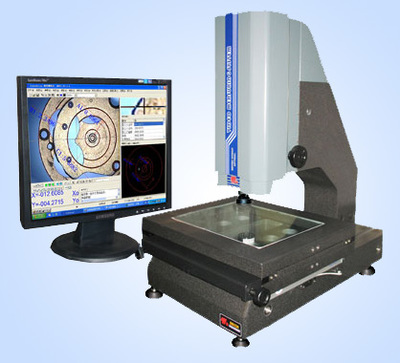

as a professional supplier of precision temperature control equipment, can achieve an environmental temperature control accuracy of ±0.002℃ and cleanliness up to Class 1 (better than ISO class 1). This data is at the leading level in the industry, providing reliable environmental protection for precision manufacturing and the operation of precision instruments. It has already served many leading chip semiconductor companies and national key laboratories. It provides non-standard customization of equipment based on different user needs through the following methods.

First, determine the environmental requirements and goals. Based on specific production or experimental needs, clarify the target values for various parameters such as temperature, humidity, and cleanliness; and confirm the external environmental parameters of this environment. For example, in the photolithography process of semiconductor chips, slight changes in temperature will cause the photolithography pattern to deform, affecting the function and performance of the chip, so the temperature control accuracy is extremely high; while in the manufacturing process of precision optical components, dust particles in the air may scratch the surface of the components, reducing the optical performance, so the cleanliness must meet strict standards. Only by clearly defining the goals can subsequent work be carried out purposefully.

Second, clarify the size of the space with high-precision environmental requirements, and build an environmental control system. Build an external framework according to the required space size, select appropriate equipment for temperature control within the framework space, and arrange it reasonably to ensure that the temperature is evenly distributed throughout the space. In terms of cleanliness, establish a complete air filtration system to filter impurities in the air layer by layer. At the same time, optimize airflow organization, reduce air vortices, and prevent pollutants from accumulating in the space. In addition, it is also necessary to consider the control of other environmental factors such as humidity and air pressure, equip corresponding regulating equipment, and achieve comprehensive control of environmental parameters.

Third, implement intelligent monitoring and feedback. Deploy high-precision sensors to monitor various parameters in the environment in real time, transmit the data to the intelligent control system, perform intelligent control, and restore the environment to stability. At the same time, the intelligent system can also generate detailed operation reports and data analysis charts to help managers understand the environmental change trends, find potential problems in time, and optimize them.

Finally, establish a complete maintenance system. Regularly maintain and maintain the environmental control system, including cleaning equipment, replacing filter cartridges, calibrating sensors, etc., to ensure that the equipment is always in good operating condition. At the same time, develop contingency plans to deal with emergencies such as equipment failures and power outages, minimizing the impact on environmental stability.

Creating a precision environment with ±0.005℃ fluctuation and ISO Class 3 cleanliness is a complex system project. By clarifying goals, building systems, intelligent monitoring, and improving maintenance, this goal can be effectively achieved, providing stable and reliable environmental protection for high-end industries and scientific research activities, and promoting the industry to continuously develop towards higher precision and higher quality.

Here is the title one h1 placeholder text

More news