Temperature control solutions for semiconductors, medical, and laser manufacturing - Extreme Measurement (Nanjing) Technology Co., Ltd.

Release time:

2025-06-04

From ±1℃ to ±0.001℃: A Millikelvin-Level Temperature Control Revolution - How Jike's High-Precision Water-Cooled Chiller Defines a New Industry Benchmark.

I. Core Industry Pain Points: When Temperature Fluctuations Become a Technological Bottleneck

In high-end manufacturing and scientific research, minor temperature control deviations are hindering technological breakthroughs :

Semiconductor lithography Extreme ultraviolet (EUV) lithography machines require cooling water temperature fluctuations ≤ ±0.001℃. Traditional units with ±0.5℃ accuracy can cause photoresist deformation, resulting in nanometer-level linewidth deviations and losses exceeding $500,000 per process.

Cryo-EM imaging Biological samples need to be maintained at -180℃ with ±0.1℃ stability. Temperature fluctuations exceeding the threshold will cause ice crystals to damage the protein structure, degrading 3D reconstruction resolution from 3Å to 8Å, rendering the research results worthless.

High-power laser processing When the optical fiber laser temperature drifts > ±0.02℃, the thermal lens effect causes the beam focus to shift by 20μm, increasing the roughness of the carbon steel cutting surface by 300% and causing a surge in the defect rate.

Technical essence Traditional water-cooled units are limited by the hysteresis of PID control, scaling and attenuation of heat exchangers, and single-point failure risks, and cannot meet the "zero-tolerance" requirements of ultra-precision scenarios.

II. Jice Technology Architecture: A Tripartite Milli-Kelvin Temperature Control Fortress

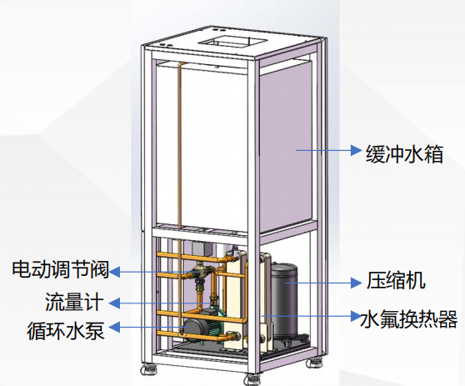

Precision water-cooled chilled water temperature control technology

It uses a self-developed high-precision temperature acquisition module to accurately measure the real-time supply water temperature and transmit it to the controller. The chilled water valve is steplessly adjustable, and the electric heater is steplessly adjustable. Using PID algorithm and step-by-step temperature control patent technology, it performs proportional, integral, and differential calculations and outputs control during operation, keeping the supply water temperature stable.

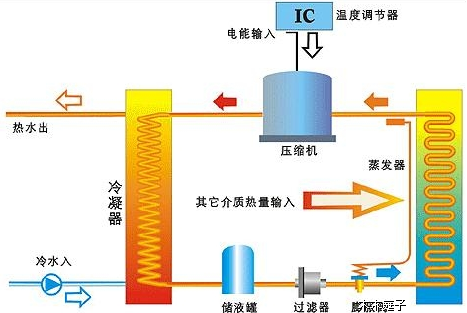

It operates based on the reverse Carnot cycle principle, transferring heat from a low-temperature heat source to a high-temperature heat source by consuming mechanical energy (or electrical energy) to achieve a cooling effect.

The refrigerant flows through the evaporator → compressor → condenser → expansion valve in sequence.

It uses high-precision temperature sensors to monitor the chilled water temperature in real time. Advanced PID control algorithms precisely adjust the cooling capacity. High-precision step-by-step temperature control patent design (invention patent No.: 2021108099890) Some high-end units use adaptive fuzzy control to improve control accuracy under complex operating conditions. Temperature control accuracy can reach ±0.1℃ ~ ±0.001℃, ensuring temperature stability.

Plate heat exchanger: High efficiency and compact, high heat transfer coefficient, good airtightness, small footprint, and easy to clean and maintain. The internal structure design uses microchannels; optimizes the internal flow field, improves the degree of fluid turbulence; and uses an intelligent control system to adjust operating parameters and reduce energy consumption. High-quality materials (copper, stainless steel) are used to improve corrosion resistance and heat transfer efficiency. Environmentally friendly refrigerant R410 is used.

III. Jice Product Characteristics: High Precision, High Stability, Energy-Efficient, Flexible Customization

High-precision temperature control patent technology (invention patent No.: 2021108099890) Outlet temperature control accuracy can reach up to ±0.001℃; efficient temperature control, enabling minute-level rapid temperature control and stable operation; self-developed high-precision temperature acquisition device, realizing precise temperature measurement and control; suitable for high-end manufacturing and scientific research scenarios sensitive to temperature.

1. Stability Mechanism

By monitoring load changes in real time, dynamically adjusting the compressor frequency, refrigerant flow rate, and heat exchanger heat transfer efficiency, it ensures that the temperature quickly recovers to the set value during equipment start-up and load changes, avoiding temperature fluctuations that affect precision processes (such as semiconductor wafer processing and optical component manufacturing).

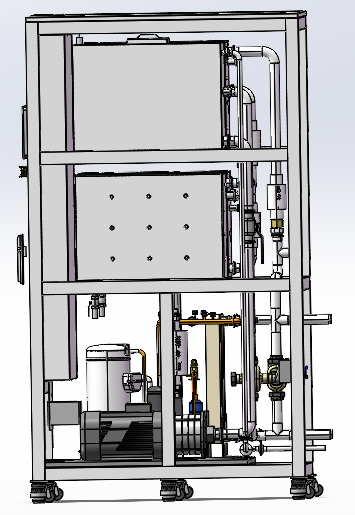

2. Reliability Design of System Components and Structure

Redundant configuration of key components: Key components such as compressors, water pumps, and controllers use redundant design, enabling dual compressor paralleling. When a single component fails, the backup component automatically switches in, maintaining continuous system operation and reducing downtime risk.

Seismic and anti-interference structure: The unit base is equipped with shock-absorbing springs or rubber pads to reduce the impact of vibration on internal components; the electrical system uses shielded cables and anti-interference filter devices to prevent control failure caused by electromagnetic interference, suitable for high-precision laboratories or industrial environments.

3. Intelligent Monitoring and Dynamic Adjustment Capability

Real-time monitoring of the entire process: Through PLC, it collects temperature, pressure, flow rate, power consumption, and other parameters in real time, forming a closed-loop data feedback. When parameters deviate from the threshold, it automatically triggers adjustments (such as increasing the cooling water flow rate and adjusting the expansion valve opening).

Adaptive load adjustment: For the dynamic load requirements of precision equipment (such as lasers and medical instruments), the unit can smoothly adjust the cooling capacity through variable frequency technology (such as compressor variable frequency and fan variable frequency), avoiding system oscillations caused by load changes and ensuring stable output.

4. Anti-attenuation Design for Long-term Operation

The heat exchanger uses stainless steel nano-coating material, combined with a water softening system, to reduce scale deposition and corrosion, maintaining long-term stable heat transfer efficiency (the heat transfer efficiency of ordinary units may decrease by 10%~20% after 1~2 years of operation, while high-precision units can be controlled within 5%).

5. Extreme Operating Condition Adaptability and Safety Protection

Wide operating condition capability: Under extreme conditions such as ambient temperatures of -10℃~45℃ and power voltage fluctuations of ±10%, it can still maintain stable refrigeration. Through anti-icing protection (such as automatic shutdown when the evaporator temperature is too low), overpressure/overcurrent protection, and other mechanisms, it prevents system failures.

Multi-level safety redundancy protection: It is equipped with no less than 6 safety devices, including high-voltage protection, low-voltage protection, current interruption protection, and motor overheating protection. When any abnormality is triggered, the system gradually reduces the load or shuts down according to the preset logic to prevent equipment damage, and simultaneously provides real-time feedback of fault information through the alarm system, improving maintenance efficiency.

1. High-efficiency energy conversion and intelligent control technology

Utilizes permanent magnet synchronous variable frequency compressors and high-efficiency permanent magnet motors, boosting energy efficiency by over 30% compared to traditional fixed-frequency units. Coupled with AI intelligent algorithms, it dynamically adjusts speed based on load, maintaining high COP values (partial load COP can reach over 5.0) across the 20%~100% load range. The heat exchanger adopts microchannel, high-efficiency corrugated tube, and other enhanced heat transfer structures, improving the heat transfer coefficient by 20%~40%, reducing temperature difference loss at the cold and hot ends, and lowering compressor power consumption.

2. System Integration Optimization The entire system adopts hydraulic balance design and variable frequency pumps, adjusting pump speed according to actual flow demand. Pump power consumption is reduced by over 40% compared to traditional fixed-speed systems. Coupled with intelligent group control technology, it enables multi-unit collaborative operation, avoiding the "overkill" phenomenon (literally "big horse pulling a small cart").

3. Low-Loss Design and Environmental Energy-Saving Technology Uses environmentally friendly refrigerants (such as R32, R410A) with ODP=0 and low GWP values. Coupled with high-efficiency sound insulation cotton and sealing structures, it reduces energy leakage and refrigerant dispersion. The electrical system adopts energy-saving transformers and harmonic suppression devices, reducing the overall power consumption density by 10%~15%. Supports dynamic sleep mode, automatically entering energy-saving standby when the load is below 10%, with power consumption dropping to less than 5% of the rated power, achieving the energy-saving goal of "cooling on demand. "

Units can be customized according to different cooling capacity requirements, with adjustable dimensions/space; meeting various installation space and usage environment requirements.

Supports multi-loop control to meet various industrial control requirements.

Currently supports single-channel and dual-channel cooling, adapting to complex process requirements.

The following table shows the product parameters for the H-series high-precision water-cooled chiller units from Jice (Nanjing) Technology Co., Ltd. for your reference. If needed, please call 400-023-8880 or click http://www.jicenj.com/ for consultation.

Model |

HSL-0150 |

HSL-0250 |

HSL-0500 |

HSL-1000 |

HSL-1400 |

HSL-2000 |

HSL-2600 |

HSL-3500 |

HSL-5000 |

|

Medium Temperature Range |

5℃-35℃, adjustable |

|||||||||

Temperature Control |

PLC constant temperature control of outlet water temperature |

|||||||||

Temperature Control Accuracy |

High precision up to ±0.002℃ /±0.001℃ |

|||||||||

Temperature Sensor |

PT100 |

|||||||||

Cooling Capacity |

10℃ |

1.5KW |

2.5KW |

5KW |

10KW |

15KW |

20KW |

26KW |

35KW |

50KW |

Circulating Water Flow |

20L/min |

25L/min |

35L/min |

50L/min |

75L/min |

100L/min |

150L/min |

200L/min |

250L/min |

|

Pressure |

2 BAR |

2 BAR |

2 BAR |

2 BAR |

2 BAR |

2 BAR |

2 BAR |

2.5 BAR |

2.5 BAR |

|

Compressor |

Sanyo, others |

|||||||||

Evaporator |

Plate Heat Exchanger |

|||||||||

Operating Panel |

10-inch Color Touch Screen |

|||||||||

Safety Protection |

With self-diagnostic function, chiller overload protection, high and low pressure protection, liquid leakage detection protection |

|||||||||

Refrigerant |

R-410A |

|||||||||

Interface Size |

DN20 |

DN20 |

DN25 |

DN25 |

DN32 |

DN40 |

DN40 |

DN50 |

DN50 |

|

Overall Dimensions (mm) |

500*800*1500 |

500*80*1500 |

600*800*1800 |

800*800*1950 |

1200*900*2000 |

1300*1000*2000 |

1500*1200*2000 |

1800*1200*2000 |

2000*1200*2000 |

|

Weight |

120Kg |

130Kg |

150Kg |

230kg |

300Kg |

360kg |

420kg |

580kg |

840kg |

|

Power Supply (50HZ) |

AC220V |

AC220V |

AC220V |

AC380V |

AC380V |

AC380V |

AC380V |

AC380V |

AC380V |

|

Casing Material |

Cold-rolled plate with powder coating |

|||||||||

Here is the title one h1 placeholder text

More news