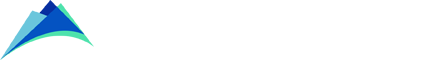

Precision Measurement

1. Temperature Requires

constant temperature conditions: Precision measurements need to be performed under constant temperature conditions because various engineering materials have thermal expansion. The standard measurement temperature is usually 20°C, but the allowable temperature fluctuation range may vary depending on the measurement accuracy and specific application scenarios. For example, in a processing workshop, if the temperature is not the standard temperature (20°C) and the measured part is not at room temperature, the measured part size needs to take into account the measurement size error caused by temperature changes and be corrected in the measurement results.

constant temperature conditions: Precision measurements need to be performed under constant temperature conditions because various engineering materials have thermal expansion. The standard measurement temperature is usually 20°C, but the allowable temperature fluctuation range may vary depending on the measurement accuracy and specific application scenarios. For example, in a processing workshop, if the temperature is not the standard temperature (20°C) and the measured part is not at room temperature, the measured part size needs to take into account the measurement size error caused by temperature changes and be corrected in the measurement results.

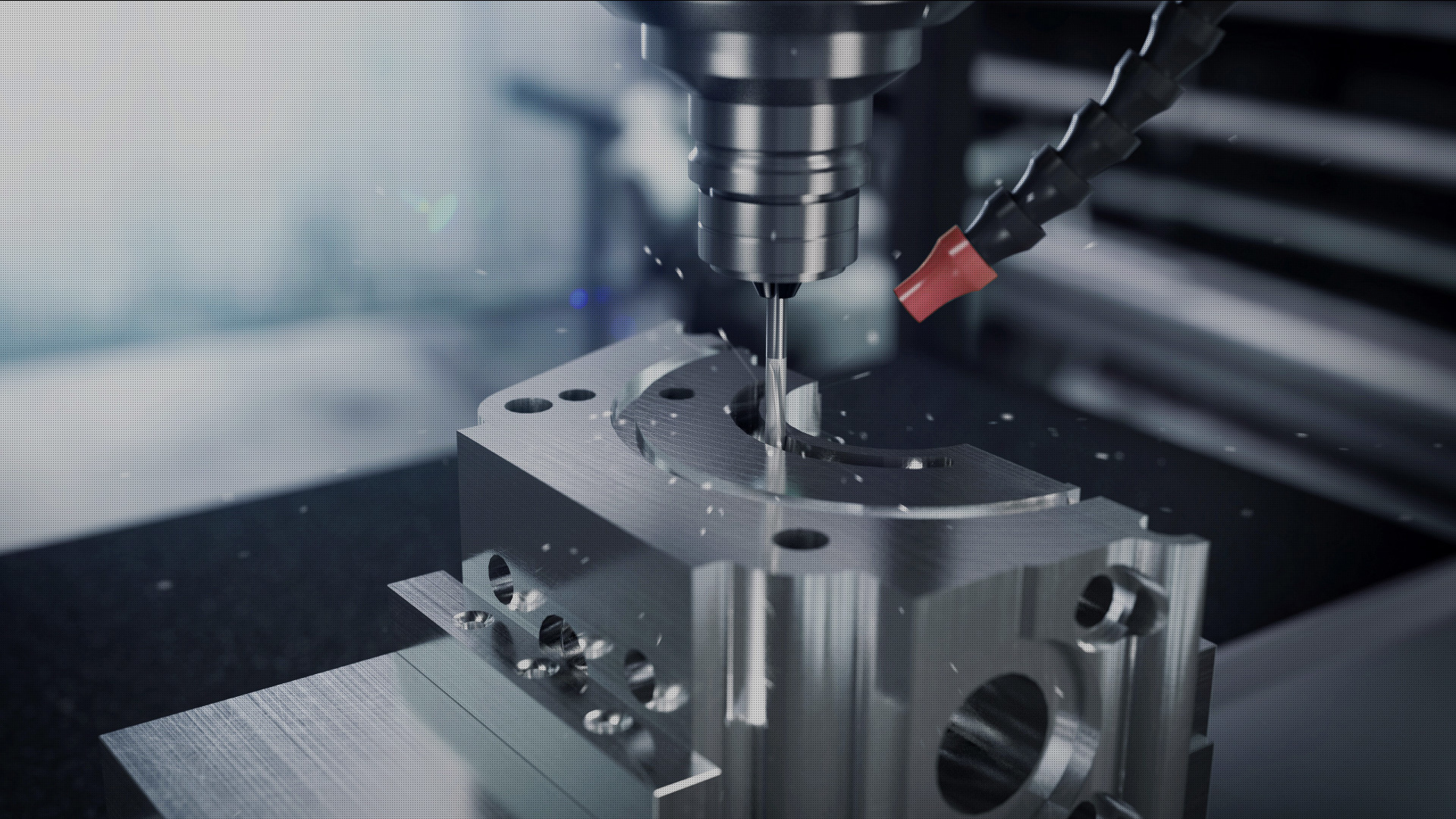

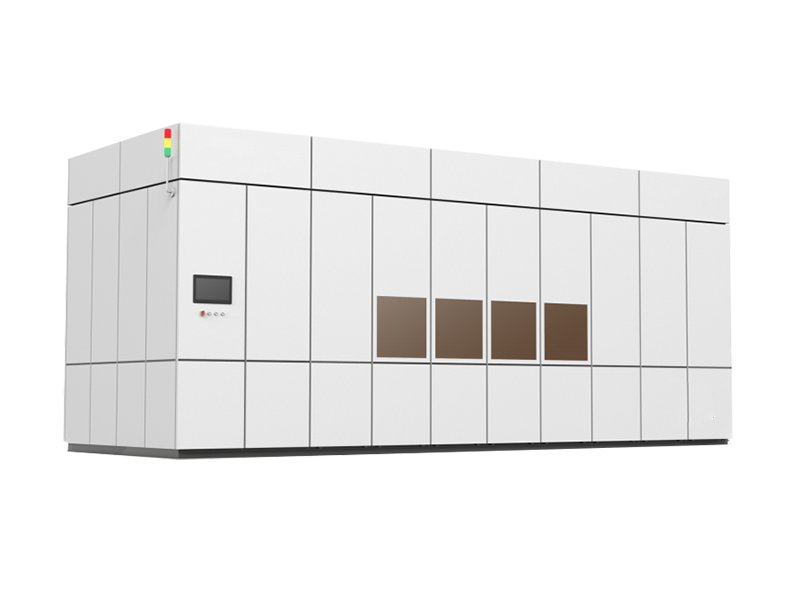

Temperature control equipment: To ensure temperature stability, precision measurement laboratories or workshops should be equipped with constant temperature equipment, such as constant temperature and humidity air conditioners, constant temperature boxes, etc., to maintain constant experimental or measurement conditions.

2. Humidity Requirements

Humidity control: Humidity also has a certain impact on precision measurement. Too high humidity may cause the material to absorb moisture and expand, affecting the measurement results; while too low humidity may cause static electricity problems and interfere with measurement accuracy. Therefore, precision measurement environments usually require that humidity be controlled within a certain range, such as 40%~60%RH (relative humidity).

Humidity monitoring: Humidity data should be monitored and recorded regularly to ensure that it meets the measurement requirements. High-precision humidity sensors and recorders can be used for monitoring.

3. Cleanliness Requirements

Particle control: Precision measurement requires a highly clean environment to prevent particles, dust and particulate matter from affecting the measurement accuracy. HEPA filters, clean benches and other technologies can be used to maintain cleanliness.

Clean room technology: In some high-precision measurement situations, it may be necessary to establish a clean room or clean bench to further reduce the particle content in the air.

Cleanliness testing: The cleanliness of the measurement environment should be tested regularly to ensure that it meets the relevant standards. Cleanliness testing can be performed using equipment such as laser dust particle counters.

4. Anti-microseismic Requirements

The precision measurement industry has extremely strict requirements for microseismic resistance, because microseismicity may introduce subtle errors, thus affecting the accuracy and reliability of the measurement results. In the field of precision measurement, fine motion error is a key issue, which is mainly caused by subtle mechanical vibrations or external interference. These vibrations may come from environmental factors, such as temperature changes, airflow, etc., or from the characteristics of the measurement equipment itself, such as the operation of motors and gears.

In order to meet the high requirements of resisting microseismic events, the precision measurement industry usually takes a series of measures to reduce vibration interference. First, in the planning of the measurement environment, the precision measurement operation will be carried out in a location with stable geological conditions and far away from the main vibration source to reduce the impact of external vibration on the measurement results. At the same time, micro-vibration control measures will be taken, such as establishing a closed measurement system, using constant temperature equipment, controlling airflow, etc., to reduce the interference of environmental factors on the measurement system.

*The above content is for reference only. For specific equipment selection, please contact us to customize the solution according to your site conditions.

Related Products

Polar Measurement (Nanjing) Technology Co., Ltd., as a mature manufacturer of high-precision environmental control equipment, we focus on innovation and development, and are committed to providing customized environmental control solutions for global enterprises, with strict temperature, humidity and cleanliness standards. Inject efficiency into your production environment.

immediate consultation

You can leave us your needs or suggestions online, and we will reply to you as soon as we receive them.